Marlow White's swords and sabers have ceremonial blades. As such, they are built to strict military regulations to be used in drills, ceremonies, and displays. These blades are of the highest quality but are not sharpened for use as a weapon.

Army Saber Etches

Return to the Army Saber Comparison page

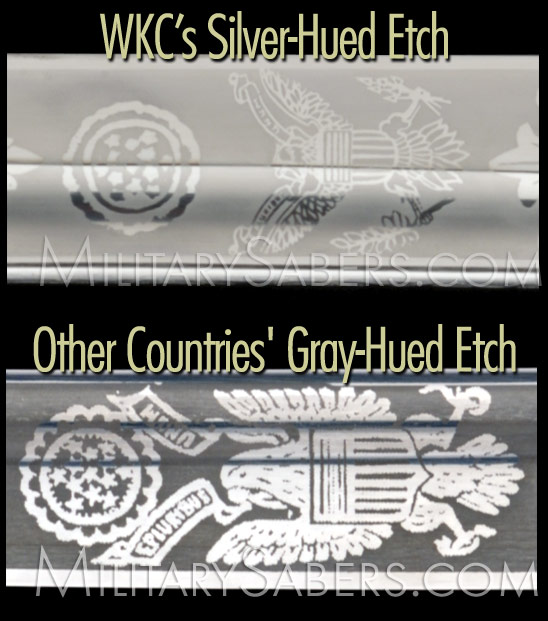

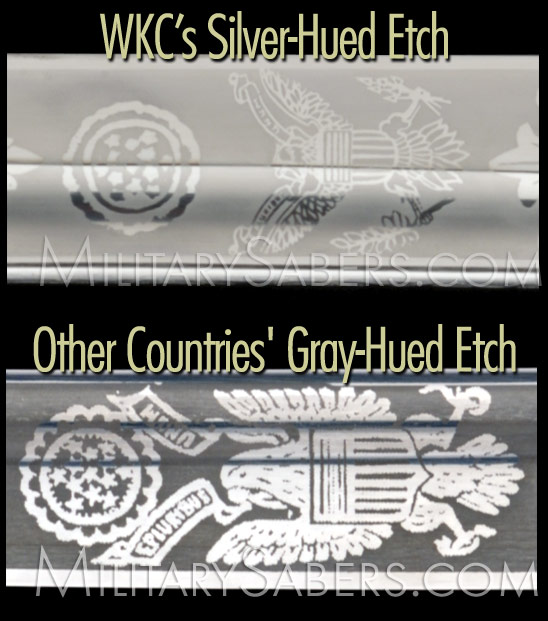

The etch is perhaps the most difficult to depict by photograph because of the difference in saber materials, the inability to depict the depth of the etch, and the way the light reflects in unretouched images.

In all cases the horizontal "lines" that appear in the images are a result of light reflecting off of the bevel and the blood groove in the blades. All images are completely unretouched, so we did not remove these lines.

The differences among the etches are very difficult to depict and are best determined by seeing them and feeling them in person. We will attempt, however, to describe the differences we saw:

- Color: The color difference is perhaps the most evident. WKC's saber-blade etch has a finer, more refined, and more polished look, a result of first nickel-plating the stainless-steel blades. The acid used in etching reacts differently with the nickel than with the steel blades used by most other manufacturers, resulting in a silver hue rather than a gray hue from the steel. Army specifications allow nickel-plating the blade; we prefer the result of WKC's additional effort which achieves a more intricate, brilliant, and jewel-like finish.

- Detail: WKC etches are intricate and very detailed. All sabers were photographed at the exact same size, but you'll notice the incredible detail difference between the eagle in WKC's etch and the eagle in the other countries' etches (e.g., the feathers, the olive branch, the arrows, etc.). The best way to compare the differences is to click on any image below and view the ultra-high-resolution image. We, subjectively, feel there is no comparison.

- Depth: The depth of the etch is perhaps impossible to depict by photo. The depth is determined by how much acid comes in contact with the "negative" part of the blade over a period of time. WKC immerses the blade in an acid bath to achieve a uniform etch; the depth of the etch is determined by the time it stays in the bath. Some countries brush the acid on, which results in a very superficial etch and can disrupt the uniformity of the etch. One can feel WKC's etch with a fingernail; no other manufacturer's etch we saw came close to the depth of WKC's etch.

- Uniqueness: You may note the similarities (perhaps one copied the other?) between Country One's and Country Two's etches. The specifications state that the etch must include the national-seal eagle, the intertwined and scripted US, the ivy, etc.; however, the exact pattern is determined by each manufacturer's artisan. WKC has been using their own unique, intricate etch on US Army Sabers for decades.

Marlow White - WKC Army Saber Etch Detail:

"Country One" Army Saber Etch - Detail:

"Country Two" Army Saber Etch - Detail:

Return to the Army Saber Comparison page

The etch is perhaps the most difficult to depict by photograph because of the difference in saber materials, the inability to depict the depth of the etch, and the way the light reflects in unretouched images.

In all cases the horizontal "lines" that appear in the images are a result of light reflecting off of the bevel and the blood groove in the blades. All images are completely unretouched, so we did not remove these lines.

The differences among the etches are very difficult to depict and are best determined by seeing them and feeling them in person. We will attempt, however, to describe the differences we saw:

- Color: The color difference is perhaps the most evident. WKC's saber-blade etch has a finer, more refined, and more polished look, a result of first nickel-plating the stainless-steel blades. The acid used in etching reacts differently with the nickel than with the steel blades used by most other manufacturers, resulting in a silver hue rather than a gray hue from the steel. Army specifications allow nickel-plating the blade; we prefer the result of WKC's additional effort which achieves a more intricate, brilliant, and jewel-like finish.

- Detail: WKC etches are intricate and very detailed. All sabers were photographed at the exact same size, but you'll notice the incredible detail difference between the eagle in WKC's etch and the eagle in the other countries' etches (e.g., the feathers, the olive branch, the arrows, etc.). The best way to compare the differences is to click on any image below and view the ultra-high-resolution image. We, subjectively, feel there is no comparison.

- Depth: The depth of the etch is perhaps impossible to depict by photo. The depth is determined by how much acid comes in contact with the "negative" part of the blade over a period of time. WKC immerses the blade in an acid bath to achieve a uniform etch; the depth of the etch is determined by the time it stays in the bath. Some countries brush the acid on, which results in a very superficial etch and can disrupt the uniformity of the etch. One can feel WKC's etch with a fingernail; no other manufacturer's etch we saw came close to the depth of WKC's etch.

- Uniqueness: You may note the similarities (perhaps one copied the other?) between Country One's and Country Two's etches. The specifications state that the etch must include the national-seal eagle, the intertwined and scripted US, the ivy, etc.; however, the exact pattern is determined by each manufacturer's artisan. WKC has been using their own unique, intricate etch on US Army Sabers for decades.

Marlow White - WKC Army Saber Etch Detail:

"Country One" Army Saber Etch - Detail:

"Country Two" Army Saber Etch - Detail: